Taśmy transportujące

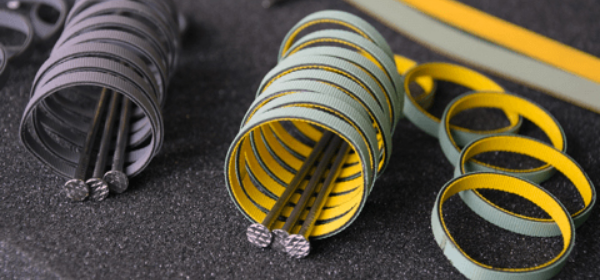

Taśmy transportujące / transporterowe oferowane przez firmę Enitra w ponad 90% należą do tzw. lekkich syntetycznych taśm transportujących....

Taśmy transportujące / transporterowe oferowane przez firmę Enitra w ponad 90% należą do tzw. lekkich syntetycznych taśm transportujących. Pozostały procent stanowią taśmy tkaninowo - gumowe do zastosowań ogólnych i do transportu pionowego…